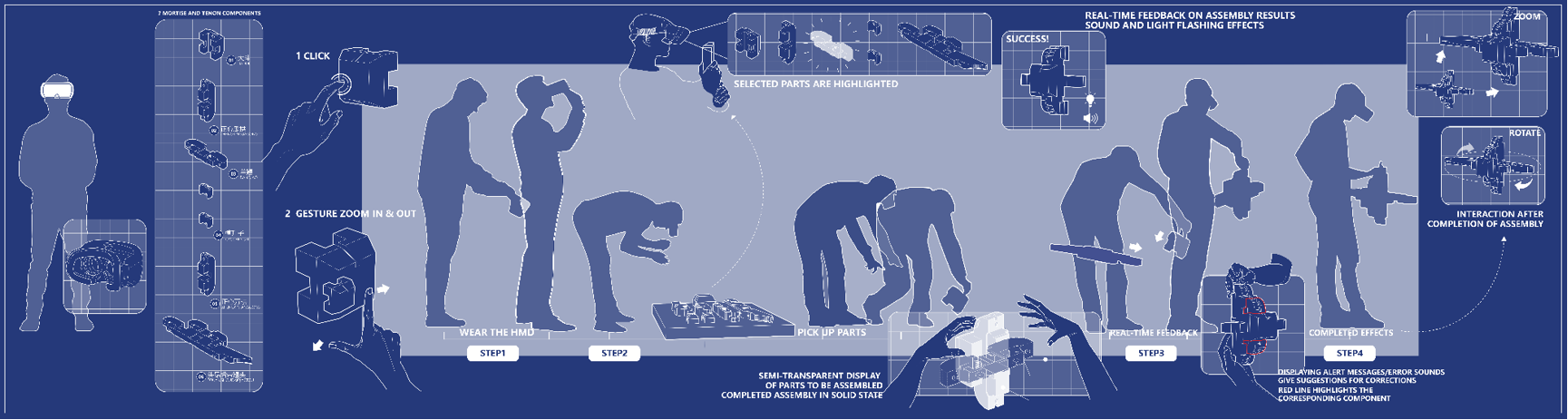

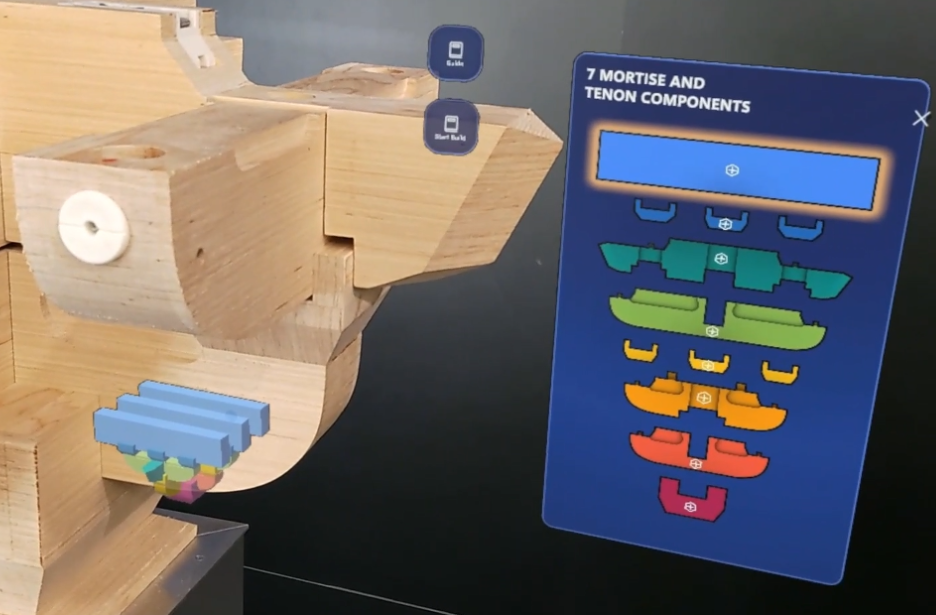

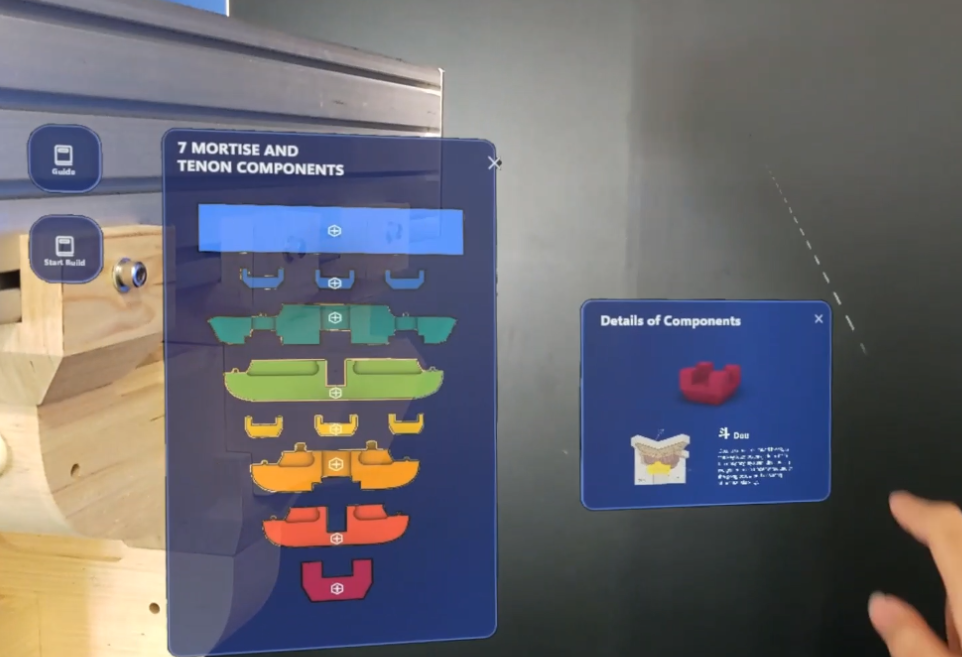

While a good component system may follow similar principles to the flat-pack furniture introduced by IKEA, the complexity of the construction industry is significantly higher. Workers responsible for assembling intricate building components are likely unfamiliar with the parts, need to use unfamiliar hardware, and must adhere to less obvious assembly sequences. To address this challenge, our proposed solution leverages virtual/digital twins, pre-programmed assembly sequences, extended reality (XR) glasses, and physical feedback and verification. This approach provides workers with real-time guidance and feedback during the assembly process, enhancing both efficiency and accuracy.

尽管良好的组件系统会遵循类似于宜家(IKEA)推出的拆装家具的规则,但建筑行业的复杂性要远高得多。负责组装复杂建筑组件的工人很可能从未见过该部件,需要使用不熟悉的硬件,并且需要遵循不太明显的组装顺序。为应对这一挑战,我们提出的解决方案利用了虚拟/数字孪生、预编程的组装序列、扩展现实(XR)眼镜以及物理反馈和验证。这种方法能够帮助工人在组装过程中获得实时指导和反馈,从而提升组装效率和准确性。